35

NEW- SHANGHAI ALIGNED Machinery Thin Film Making Machine OZM-340 with Slitting Machine KFG-38

1 NEW- SHANGHAI ALIGNED Machinery Thin Film Making Machine OZM-340 with Slitting Machine KFG-380

NEW IN CRATE - NEVER USED IN PRODUCTION

PURCHASED NEW IN 2019

* MANUAL INCLUDED

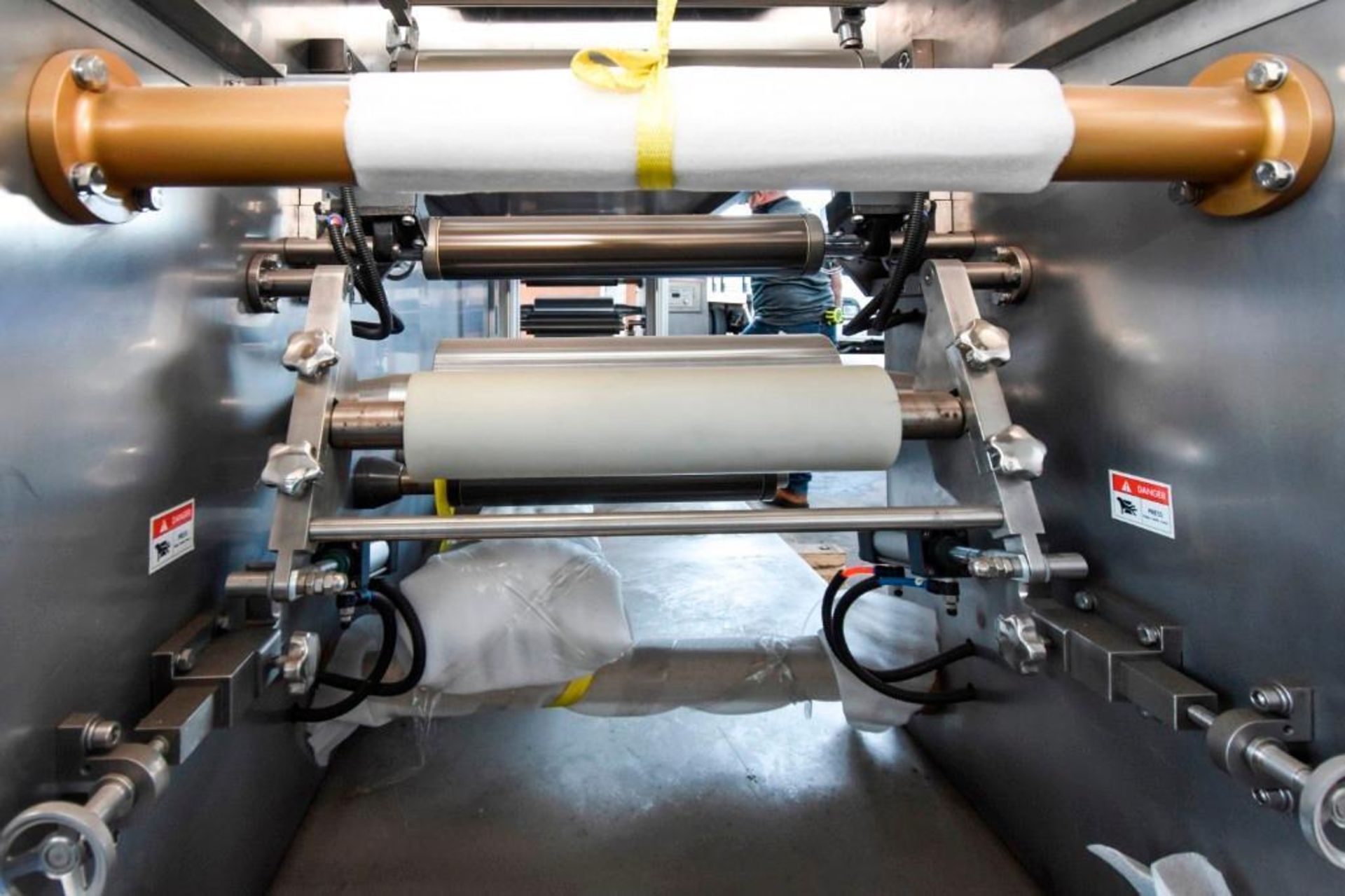

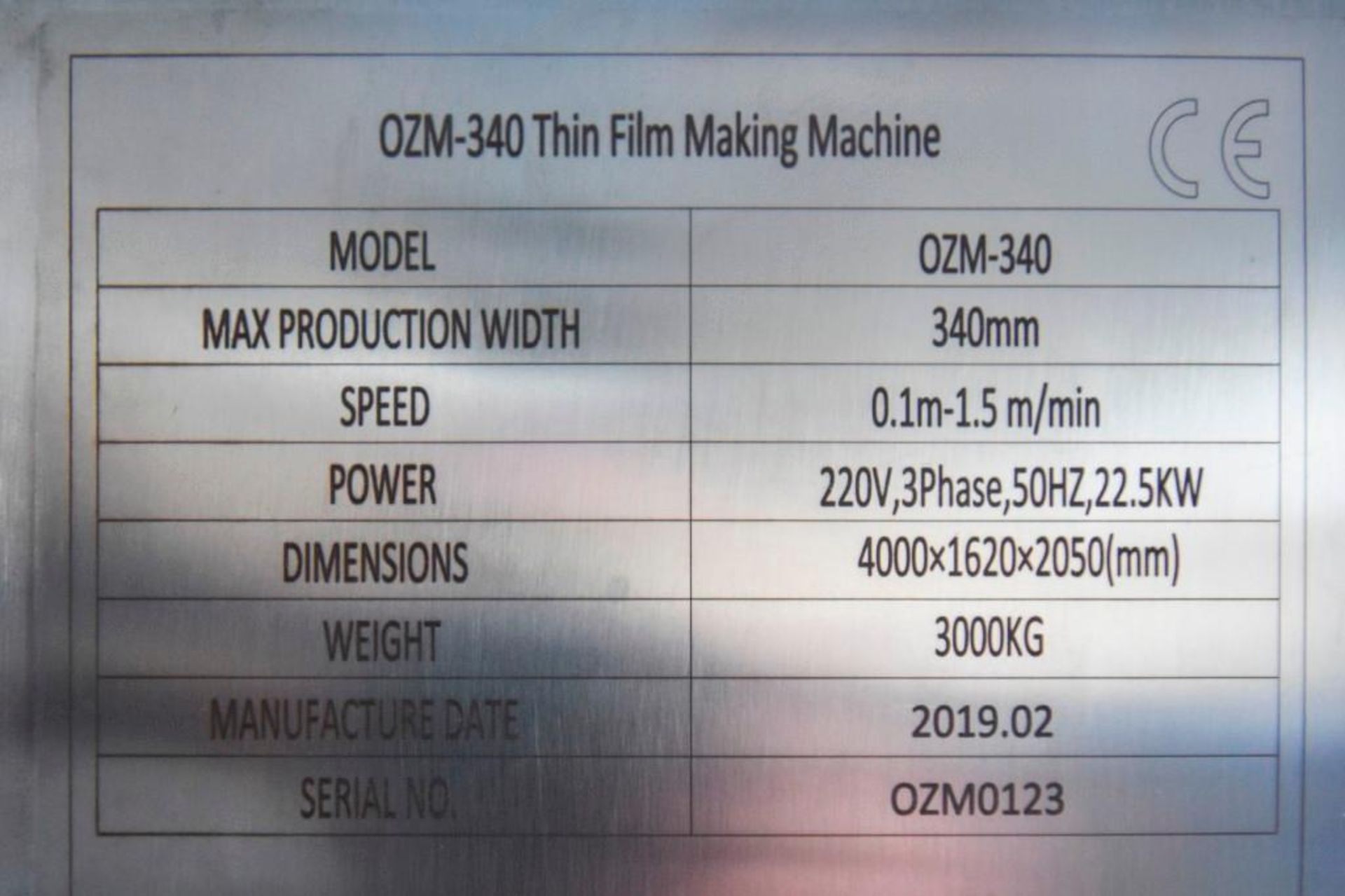

SHANGHAI ALIGNED Thin Film Making Machine OZM-340

MFG: SHANGHAI ALIGNED Machinery

MDL: OZM-340

www.aligned.com.cn

General Info:

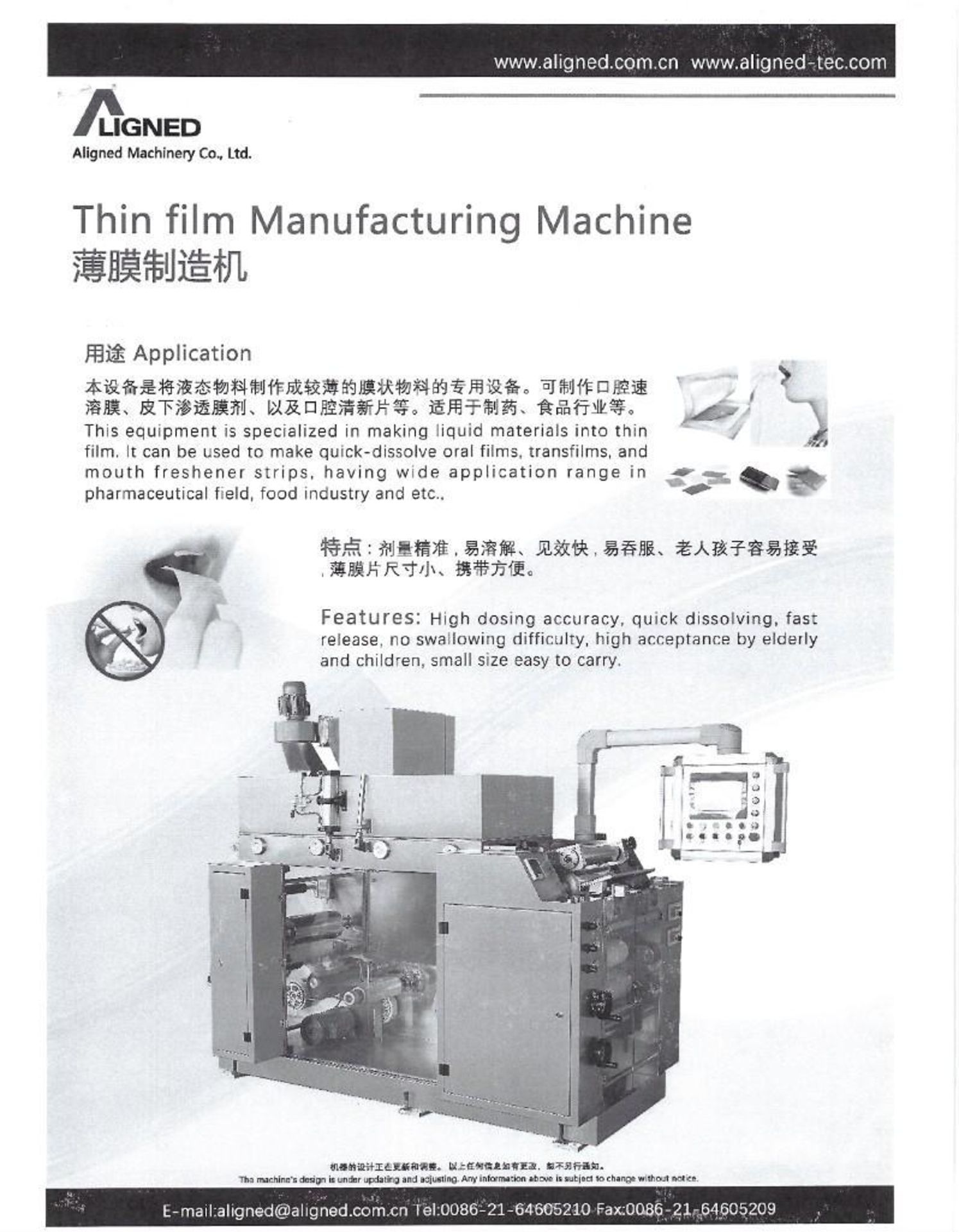

OZM-340 is specialized in making liquid materials into a thin film. It can be used to make quick dissolve oral films, transfilms, and mouth freshener strips, having a wide application range in the pharmaceutical, nutraceutical, and food industry.

Application

Oral Disintegration film Making Machine, is designed to manufacture membrane products from liquid materials. Adopts frequency conversion speed control and automatic control technology of machine, electric, light and gas, and innovates the design according to the "GMP" standard and the “UL” Safety Standard of the pharmaceutical industry.

The Thin Film Making Machine has the functions of film making, air drying and other features. All the data parameters are regulated by the PLC control panel. The model is for the new thin film drugs for continuous improvement, innovation and research and development, its comprehensive performance to the leading domestic level, the technology to fill the gaps, and imported equipment more practical and economical.

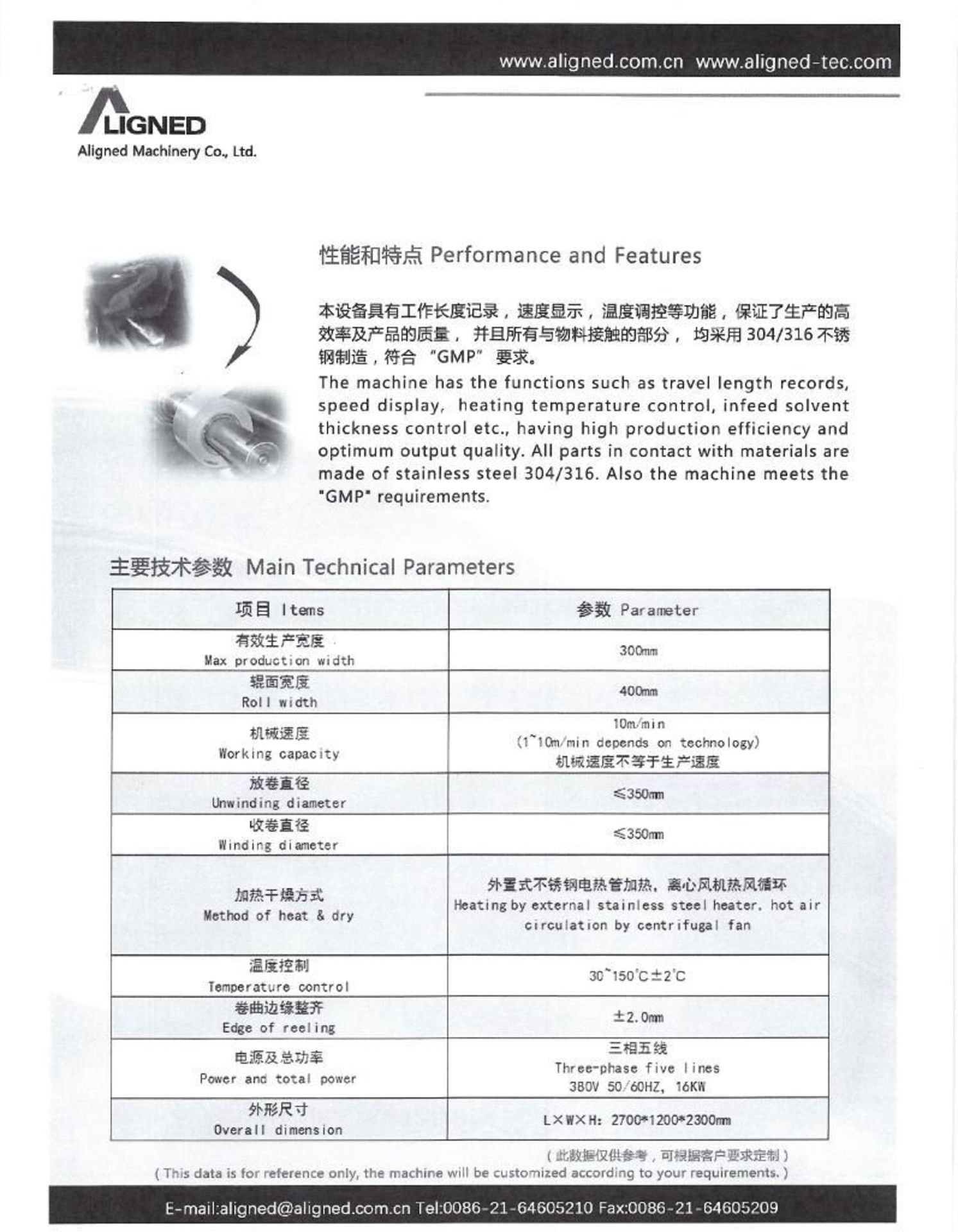

Max production width: 360mm

Roll Width: 400mm

Speed: 0.1-1.5m/min Depends on technology

Unwinding Diameter: ≤φ350mm

Winding Diameter: ≤φ350mm

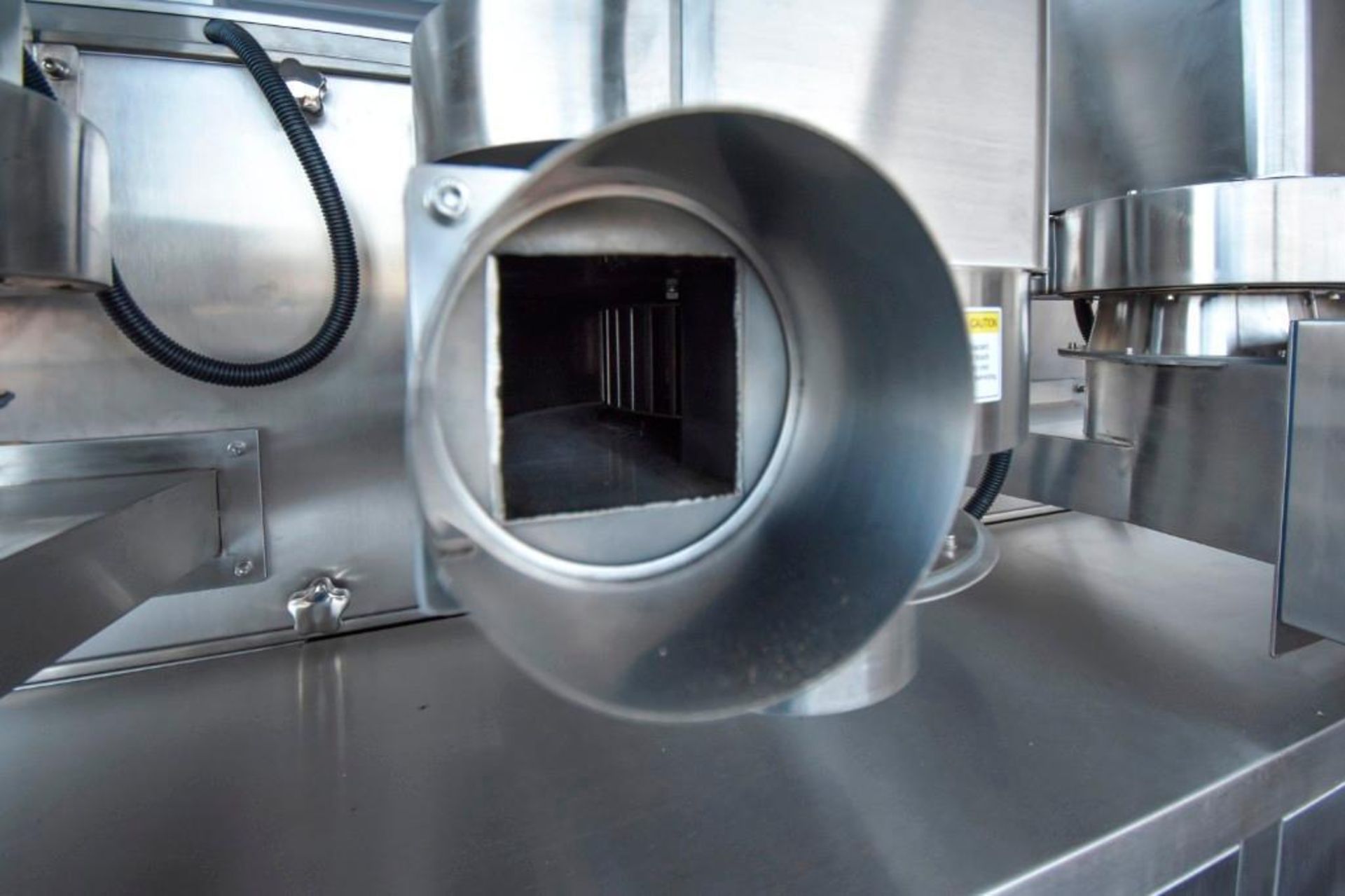

Method of heat & dry: Heating by external stainless-steel

heater, hot air circulation in

centrifugal fan

Temperature control: 30-80℃±2℃

Edge of reeling: ±3.0mm

Power Supply: 16Kw

Overall dimension: 2980*1540*1900mm

Performance and Features

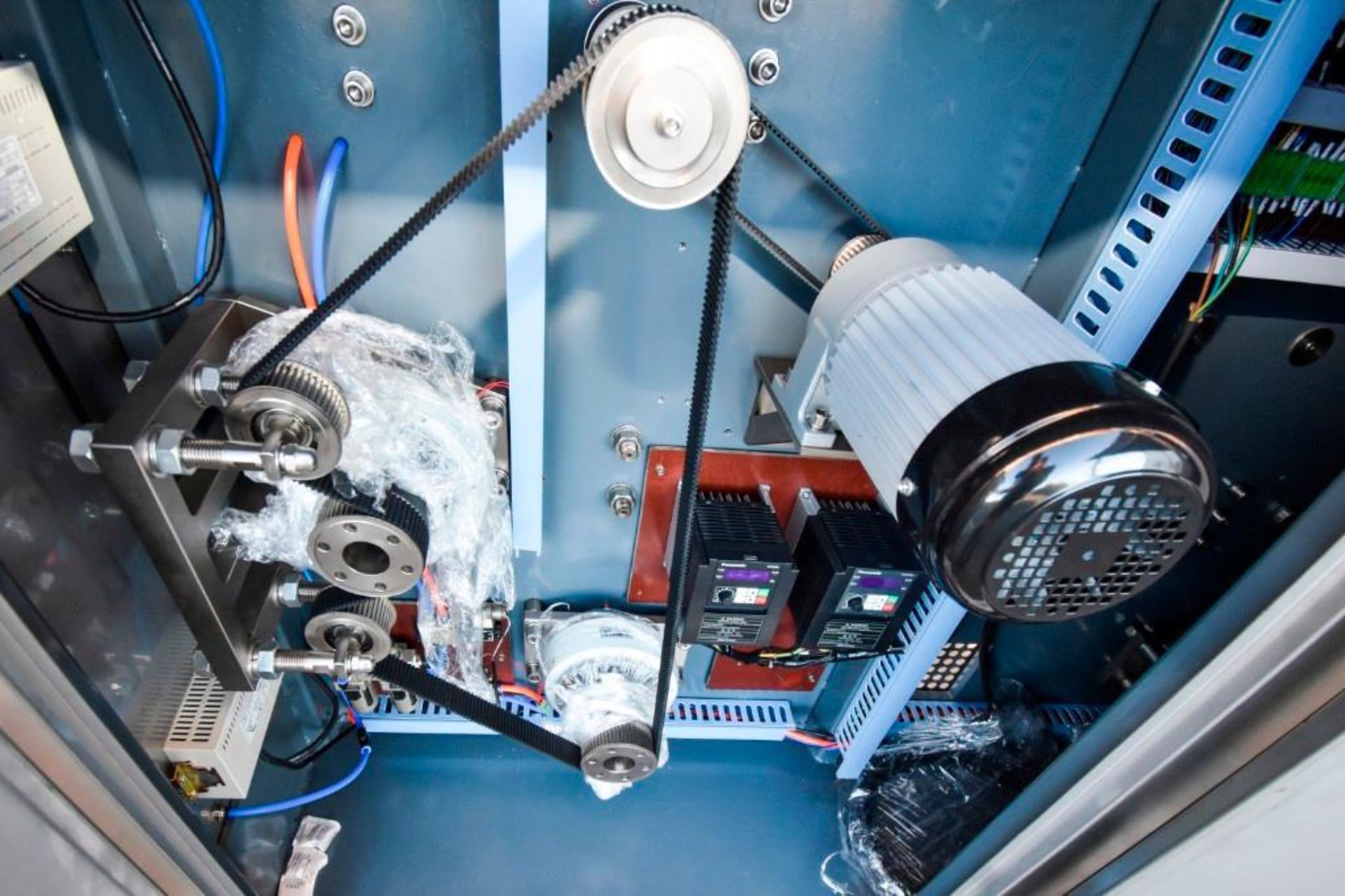

The Film Making Machine is suitable for the coating composite production of paper, film, metal foil and etc. The whole power system adopts the AC variable frequency stepless speed regulation system composed of frequency converter. The winding is manually controlled by the magnetic clutch tension.

This machine uses the Main body plus attachment structure, which let the stations install and disassemble separately. The installation is positioning by cylindrical pin and fastening by screws, easy and convenient to assemble.

The machine also has the functions of automatic working length recording, speed display, oven temperature automatic control and so on. These functions ensure the high efficiency of production and product quality.

All parts in contact with the material and other parts, are made of stainless steel and non-toxic materials, meet the "GMP" requirements. All electrical components, wiring and operating options are in compliance with the "UL" safety standards.

SHANGHAI ALIGNED Slitting Machine KFG-380

MFG: SHANGHAI ALIGNED Machinery

MDL: KFG-380

General Info:

KFG-380 is ideal for cutting and packing film strips into pouches, such as oral dissolving films, mint strips, adhesive patches, etc. The cutting station makes it easy to apply, handle and store film strips, and is dampness proof, has a perfect sealing design, strong shading, as well as flexible bag design in shape, size, and color.

Application

Automatic slitting and drying machine, which with function of peeling, humidity adjusting, slitting and winding, is used for the intermediate process of the material and prepares to adapt to the next step of packaging.

Adopts frequency conversion speed control and automatic control technology of machine, electric, light and gas, and innovates the design according to the "GMP" standard and the “UL” Safety standard of the pharmaceutical industry.

The Slitting Machine has the functions of detecting the tension, automatic feedback signal and adjustment, which will adapt to the changing needs of materials during operation. All the data parameters are regulated by the PLC control panel. The model is for the new thin film drugs for continuous improvement, innovation and research and development, its comprehensive performance to the leading domestic level, the technology to fill the gaps, and imported equipment more practical and economical.

Production Capacity: Standard 0.002m-5m/min

Finished Film width: 110-190mm(Maximum 380mm)

Raw material width: ≤380mm

Main motor power: 1.29Kw

Power supply and total power: Three Phrase Five Line, 220V 50/60Hz 1.5Kw

Air filter efficiency: 99.95%

Air pump volume flow: ≥0.40m3/min

Packing Material: Slitting composite film thickness (usually) 0.12mm

Overall dimensions: 1930×1400×1950mm

Machine package size: 2200×1600×2250mm

Total Weight: 1200Kg

Dividing material specifications

Roll type packing material: PET/Aluminum/PE composite film

Thickness: 0.10-0.12

Roll inner diameter: φ76-78mm

Material Roll outer diameter: φ350mm

Performance and Features

The Machine has the functions of peeling, slitting and adjusting humidity with the Film produced by film making machine. The frequency conversion motor is used for discharging and winding. Production efficiency can be set according to production needs, as well as automatic balancing speed and tension.

This machine uses Main body plus attachment structure, which let the stations install and disassemble separately. The installation is positioning by cylindrical pin and fastening by screws, easy and convenient to assemble.

The machine also has the functions of automatic working length recording, speed display, oven temperature automatic control and so on. These functions ensure the high efficiency of production and product quality.

All parts in contact with the material and other parts, are made of stainless steel and non-toxic materials, meet the "GMP" requirements. All electrical components, wiring and operating options are in compliance with the "UL" safety standards.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: San Diego, CA 92123

Load Out: $1040

Skidding: $1560

1 NEW- SHANGHAI ALIGNED Machinery Thin Film Making Machine OZM-340 with Slitting Machine KFG-380

NEW IN CRATE - NEVER USED IN PRODUCTION

PURCHASED NEW IN 2019

* MANUAL INCLUDED

SHANGHAI ALIGNED Thin Film Making Machine OZM-340

MFG: SHANGHAI ALIGNED Machinery

MDL: OZM-340

www.aligned.com.cn

General Info:

OZM-340 is specialized in making liquid materials into a thin film. It can be used to make quick dissolve oral films, transfilms, and mouth freshener strips, having a wide application range in the pharmaceutical, nutraceutical, and food industry.

Application

Oral Disintegration film Making Machine, is designed to manufacture membrane products from liquid materials. Adopts frequency conversion speed control and automatic control technology of machine, electric, light and gas, and innovates the design according to the "GMP" standard and the “UL” Safety Standard of the pharmaceutical industry.

The Thin Film Making Machine has the functions of film making, air drying and other features. All the data parameters are regulated by the PLC control panel. The model is for the new thin film drugs for continuous improvement, innovation and research and development, its comprehensive performance to the leading domestic level, the technology to fill the gaps, and imported equipment more practical and economical.

Max production width: 360mm

Roll Width: 400mm

Speed: 0.1-1.5m/min Depends on technology

Unwinding Diameter: ≤φ350mm

Winding Diameter: ≤φ350mm

Method of heat & dry: Heating by external stainless-steel

heater, hot air circulation in

centrifugal fan

Temperature control: 30-80℃±2℃

Edge of reeling: ±3.0mm

Power Supply: 16Kw

Overall dimension: 2980*1540*1900mm

Performance and Features

The Film Making Machine is suitable for the coating composite production of paper, film, metal foil and etc. The whole power system adopts the AC variable frequency stepless speed regulation system composed of frequency converter. The winding is manually controlled by the magnetic clutch tension.

This machine uses the Main body plus attachment structure, which let the stations install and disassemble separately. The installation is positioning by cylindrical pin and fastening by screws, easy and convenient to assemble.

The machine also has the functions of automatic working length recording, speed display, oven temperature automatic control and so on. These functions ensure the high efficiency of production and product quality.

All parts in contact with the material and other parts, are made of stainless steel and non-toxic materials, meet the "GMP" requirements. All electrical components, wiring and operating options are in compliance with the "UL" safety standards.

SHANGHAI ALIGNED Slitting Machine KFG-380

MFG: SHANGHAI ALIGNED Machinery

MDL: KFG-380

General Info:

KFG-380 is ideal for cutting and packing film strips into pouches, such as oral dissolving films, mint strips, adhesive patches, etc. The cutting station makes it easy to apply, handle and store film strips, and is dampness proof, has a perfect sealing design, strong shading, as well as flexible bag design in shape, size, and color.

Application

Automatic slitting and drying machine, which with function of peeling, humidity adjusting, slitting and winding, is used for the intermediate process of the material and prepares to adapt to the next step of packaging.

Adopts frequency conversion speed control and automatic control technology of machine, electric, light and gas, and innovates the design according to the "GMP" standard and the “UL” Safety standard of the pharmaceutical industry.

The Slitting Machine has the functions of detecting the tension, automatic feedback signal and adjustment, which will adapt to the changing needs of materials during operation. All the data parameters are regulated by the PLC control panel. The model is for the new thin film drugs for continuous improvement, innovation and research and development, its comprehensive performance to the leading domestic level, the technology to fill the gaps, and imported equipment more practical and economical.

Production Capacity: Standard 0.002m-5m/min

Finished Film width: 110-190mm(Maximum 380mm)

Raw material width: ≤380mm

Main motor power: 1.29Kw

Power supply and total power: Three Phrase Five Line, 220V 50/60Hz 1.5Kw

Air filter efficiency: 99.95%

Air pump volume flow: ≥0.40m3/min

Packing Material: Slitting composite film thickness (usually) 0.12mm

Overall dimensions: 1930×1400×1950mm

Machine package size: 2200×1600×2250mm

Total Weight: 1200Kg

Dividing material specifications

Roll type packing material: PET/Aluminum/PE composite film

Thickness: 0.10-0.12

Roll inner diameter: φ76-78mm

Material Roll outer diameter: φ350mm

Performance and Features

The Machine has the functions of peeling, slitting and adjusting humidity with the Film produced by film making machine. The frequency conversion motor is used for discharging and winding. Production efficiency can be set according to production needs, as well as automatic balancing speed and tension.

This machine uses Main body plus attachment structure, which let the stations install and disassemble separately. The installation is positioning by cylindrical pin and fastening by screws, easy and convenient to assemble.

The machine also has the functions of automatic working length recording, speed display, oven temperature automatic control and so on. These functions ensure the high efficiency of production and product quality.

All parts in contact with the material and other parts, are made of stainless steel and non-toxic materials, meet the "GMP" requirements. All electrical components, wiring and operating options are in compliance with the "UL" safety standards.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: San Diego, CA 92123

Load Out: $1040

Skidding: $1560

CBD & Cannabis Nutritional Supplement Equipment

Ends from

General delivery information available from the auctioneer

Skidding and Load out charges:

There will be loading and skidding charges added to your purchase at market rates for your convenience.

Important Information

AUCTION DATE: lots start closing on Thursday, December 17th at 10:00 am PT

LOCATION: San Diego, CA

PICKUP: TBD

RIGGING:

There is no self-rigging. All Rigging and Loadout will be completed by a contracted and approved Rigger.

INSPECTION DATES: TBD

18% Buyers Premium applies on all online purchases.

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

Terms of Sale Agreement:

SELLER RESERVES THE RIGHT TO ACCEPT OR REJECT ANY AND ALL BIDS

- Only Credit Card, Wire Transfers or Cashier’s Checks payable to Chris Hillseth Enterprises will be accepted for payment. No equipment will be removed from the sale site until payment is received by Chris Hillseth Enterprises. NO EXCEPTIONS! NO PAYMENT TAKEN ON SITE.

- While descriptions are believed to be correct, the seller’s agent or the owners make no warranties or guarantees expressed or implied, as to the genuineness, authenticity of, or defect in any lot and will not be held responsible for advertising discrepancies or inaccuracies. Everything sold AS IS and WHERE IS except as expressly made in writing. No warranties are made as to the merchantability of any items or their fitness for any purpose. Inspect before you bid, absolutely no warranty or guarantee of any kind, either written or implied.

- For bidding approval, at its discretion, Chris Hillseth Enterprises Corp may contact Bidders via email or telephone before to provide a deposit. Require a deposit of up to $10,000.00 USD (refundable without purchase) for lack of sufficient Bidspotter history e.g. first time Bidspotter registrant or negative Bidspotter history. Bidder will be notified if it is determined a deposit must be made. If Chris Hillseth Enterprises does not receive a response from its attempts to contact Buyer or if the Buyer does not provide a deposit, Chris Hillseth Enterprises reserves the right to refuse or cancel Buyer’s bids and re-sell Goods.

- Some items may have minimums or reserves. Therefore, bidder acknowledges they have been informed that Auctioneer may bid at the auction for its own account or on behalf of a third party or the seller.

- Purchaser hereby agrees to defend, indemnify and hold harmless Seller its directors, officers, employees and other agents and representatives from and against any and all liabilities, judgments, claims, settlements, losses, damages, penalties, obligations and expenses, including attorney`s fees and expenses and other professional fees and expenses, incurred or suffered by such person arising from, by reason of, or in connection with any loss, damage or injury to person or property arising from, by reason of or in connection with the Goods sold hereunder. This indemnification shall survive delivery of the Goods to Purchaser and any subsequent sale or other transfer of the Goods to a third party.

- It is the buyers’ responsibility to secure all safety equipment to meet all applicable government safety standards in using or removing items purchased.

- Sales Tax will be added to the purchase of all taxable items. Dealers who purchase for resale must file their resale permit numbers. If sales tax is not collected at the time of sale and is deemed “needed to be paid” at a later date, buyer agrees to pay all required taxes.

- Purchaser does hereby indemnify and hold harmless auctioneer and seller from any and all damages, claims or liabilities from injuries to persons or property of any type whatsoever caused during the sale or by the removal of items purchased.

- Sellers agent and Seller shall have no liability to the purchaser due to non-delivery of any item for any reason other than to return to the Purchaser the monies deposited for non-delivered items.

- In the event the purchaser fails to pay the whole of the purchase within the time set forth by the auctioneers and/or fails to comply with any of the conditions or terms of sale, the seller may retain and/or recover the deposit specified as liquidated damages and, in addition thereto, items that are not paid for can be resold at public or private sale without further notice. Any deficiency resulting from such resale shall be paid to the auctioneers by the defaulting purchaser together with all charges, fees, and expenses incurred by such resale and enforcement of the obligation hereunder.

- The Bidder becomes solely responsible for all items purchased by him immediately following his winning bid at the auction. Therefore, he is advised to further guard and insure his items at his own discretion.

- No item can, on any account, be removed before buyer receives payment in full. Removal shall be at the expense, risk and liability of the purchaser. Auctioneers shall not be responsible for items not removed within the time allowed. If equipment is not removed within specified removal time, purchaser shall be liable for any moving and storage costs incurred and, if not so removed, the items shall be deemed abandoned.

- If any shortage exists on estimated counts, an adjustment will be made if claims are made at time of removal. No adjustment will be allowed after items are removed from the premises.

- If any dispute arises between two or more bidders, the sellers’ agent may or may not put the lot up again at once, and resell.

- The sellers’ agent, when acting as agent only, is not responsible for acts of its principals.

- A 18% Buyers premium will be applied to all sales in Addition to Applicable Local and State Sales Tax.

- By accepting a sale listing catalog and signing this form the buyer agrees to these terms and any announced terms at the sale.

- You will receive notifications from us regarding your purchases.

- Seller reserves the right to accept or reject any and all bids.

- All Bills must be completed on Day of Sale unless arrangements are made with Auction House prior to bidding.

- Full Payment at Termination of Sale.

- A 3% fee will be applied to all CC orders.

- Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates.

Inspection date (day only) is:

By Appointment Only. Call 818 495 3038 to Schedule.

Inspection locations:

Various Locations, call for specific item.

Inspection by appointment only.

Call or Email Logan Hillseth logan@chrishillsethenterprises.com or Patrick Hillseth at (818)495-3038 patrick@chrishillsethenterprises.com