51

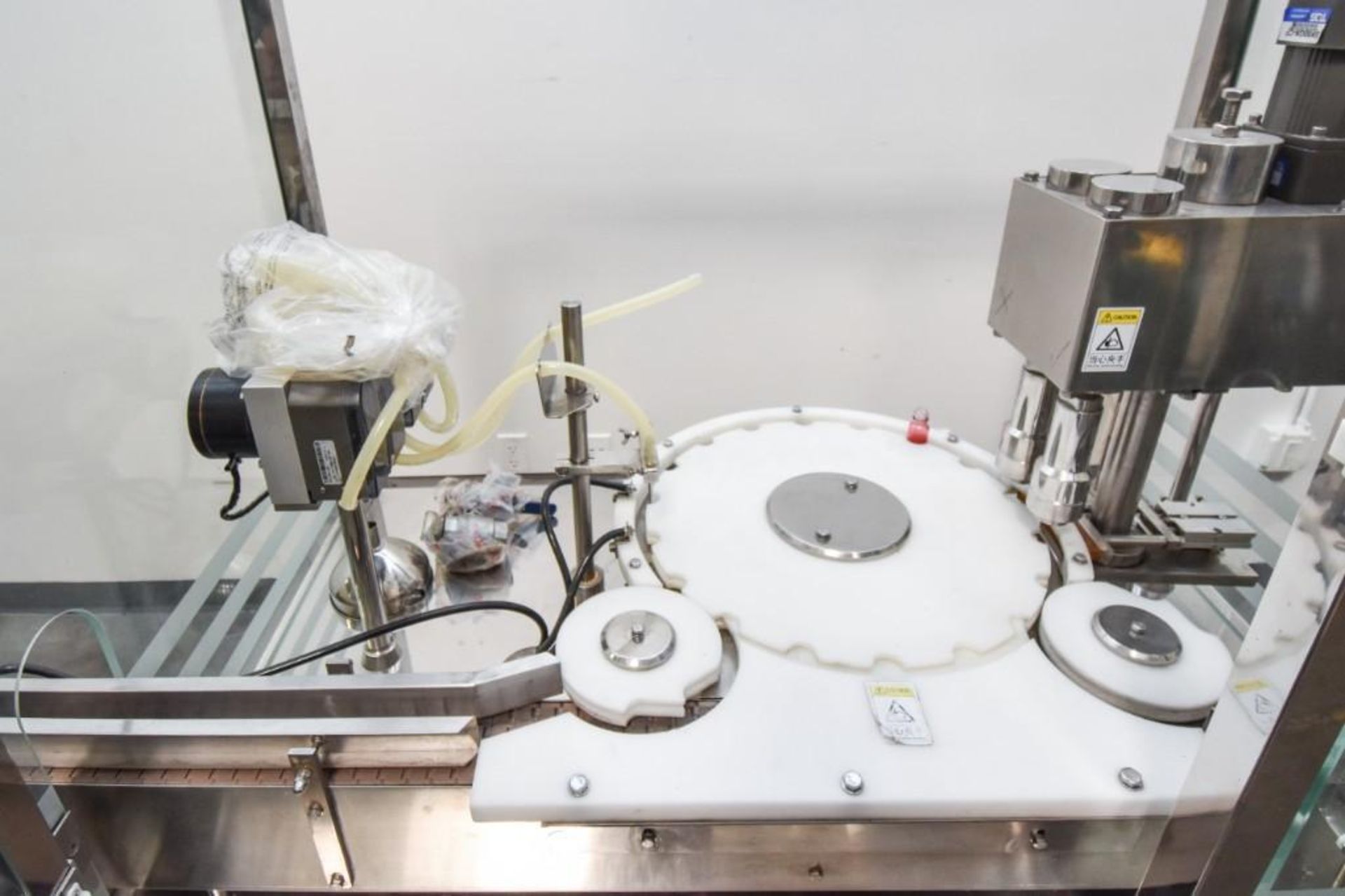

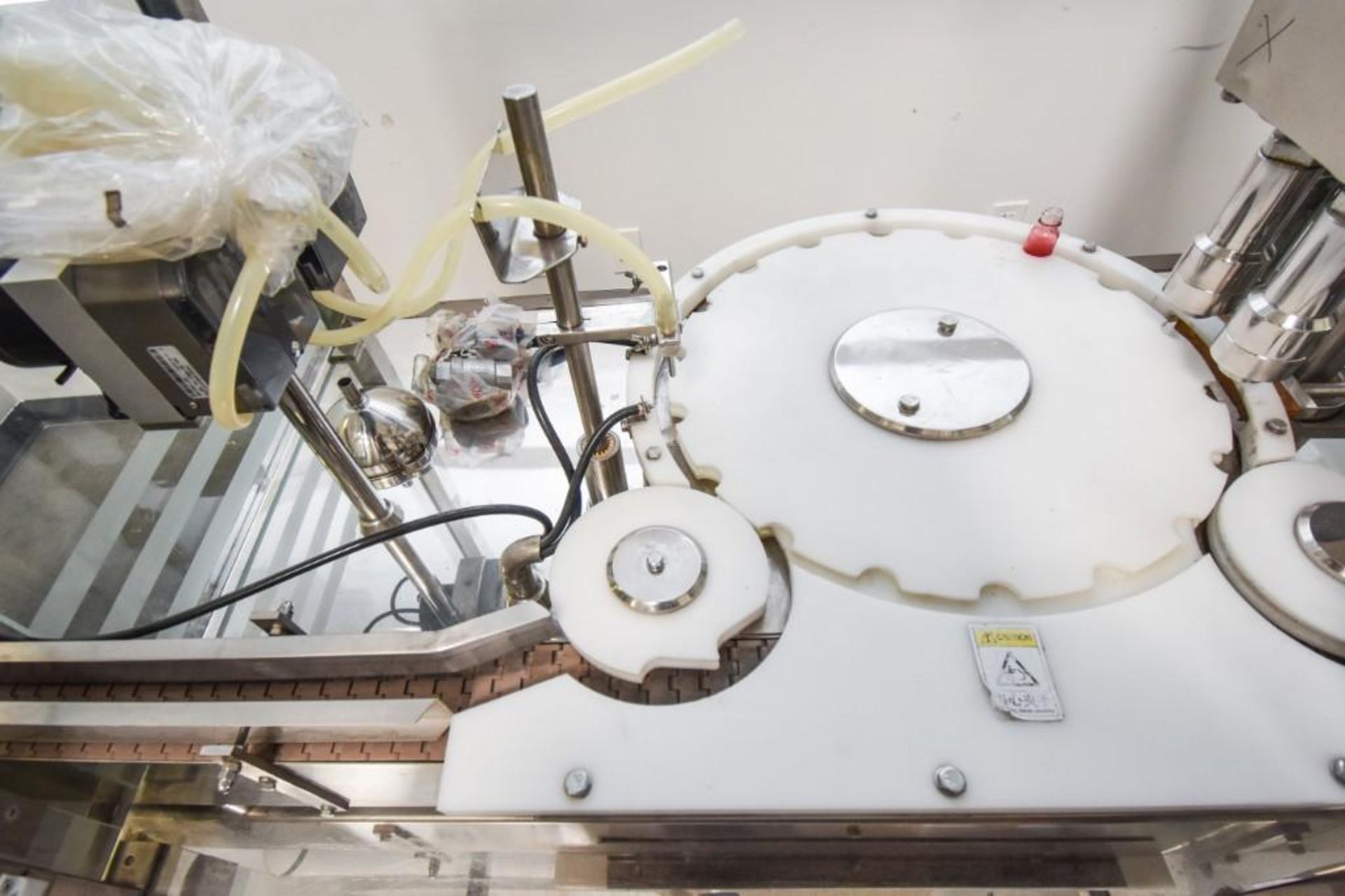

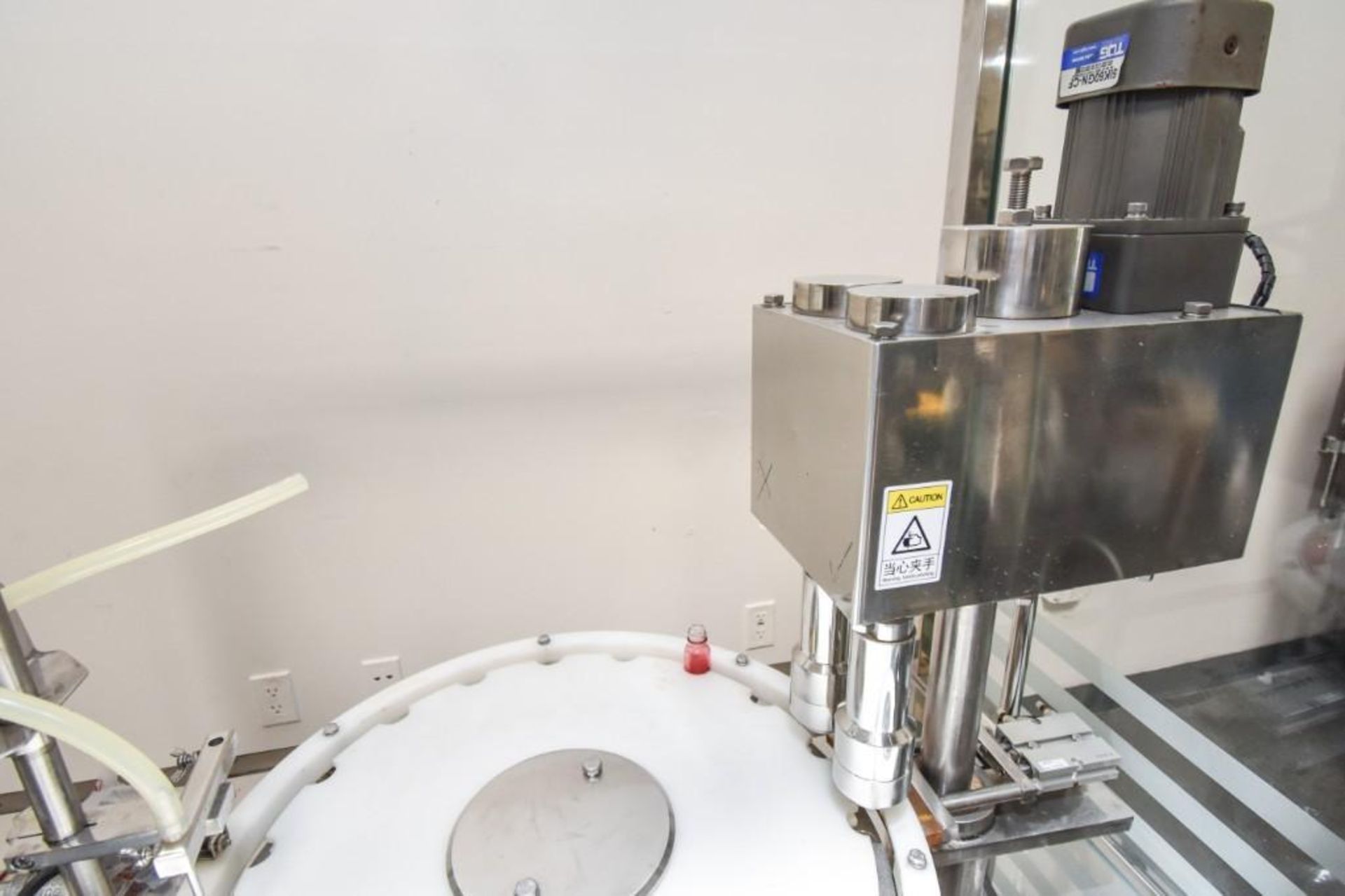

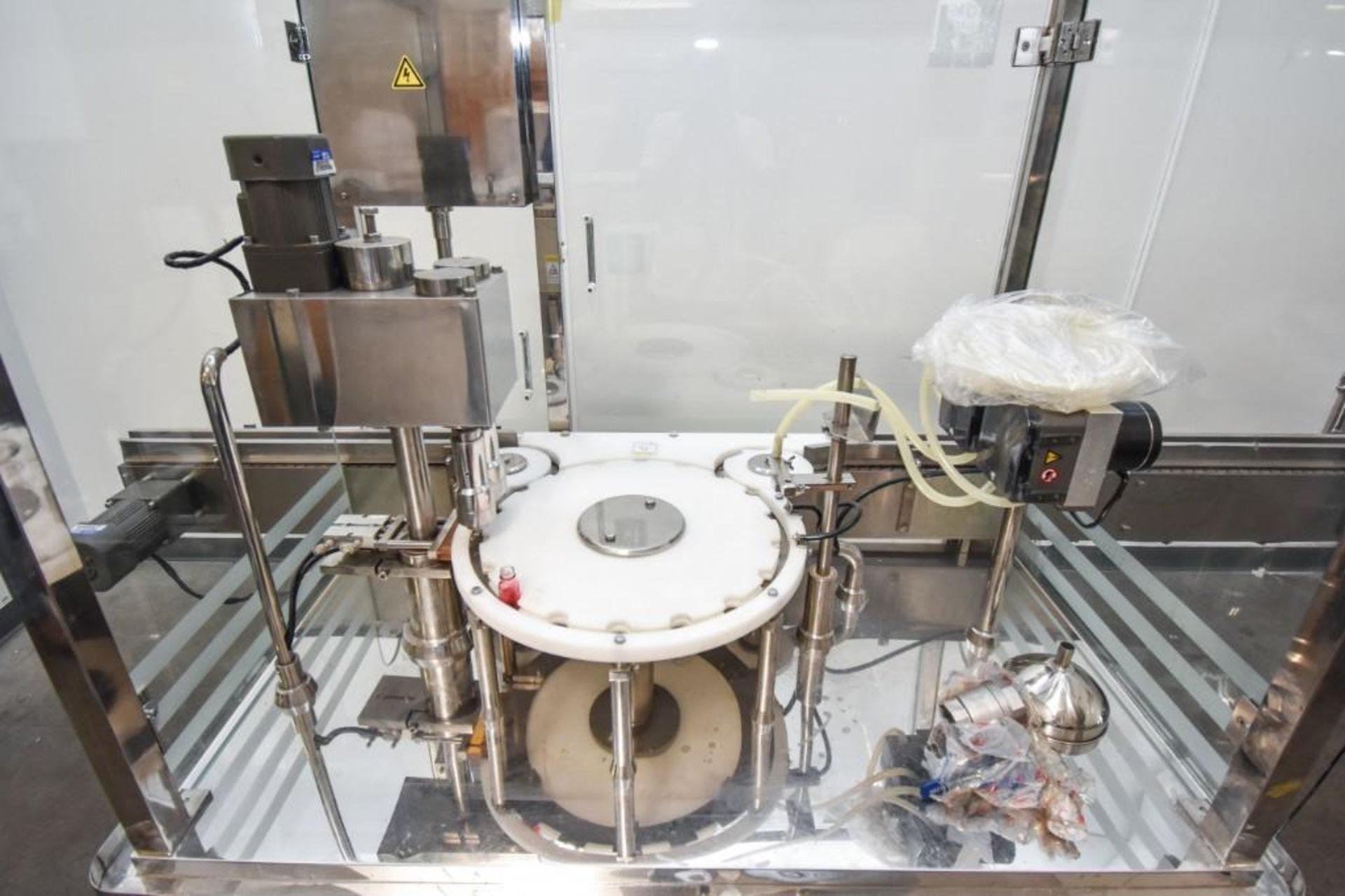

Dual Head Liquid Filling/ Capping Machine with Vibratory Cap Feeder and Mixing Tank

1 - Dual Head Liquid Filling/ Capping Machine with Vibratory Cap Feeder and Mixing Tank

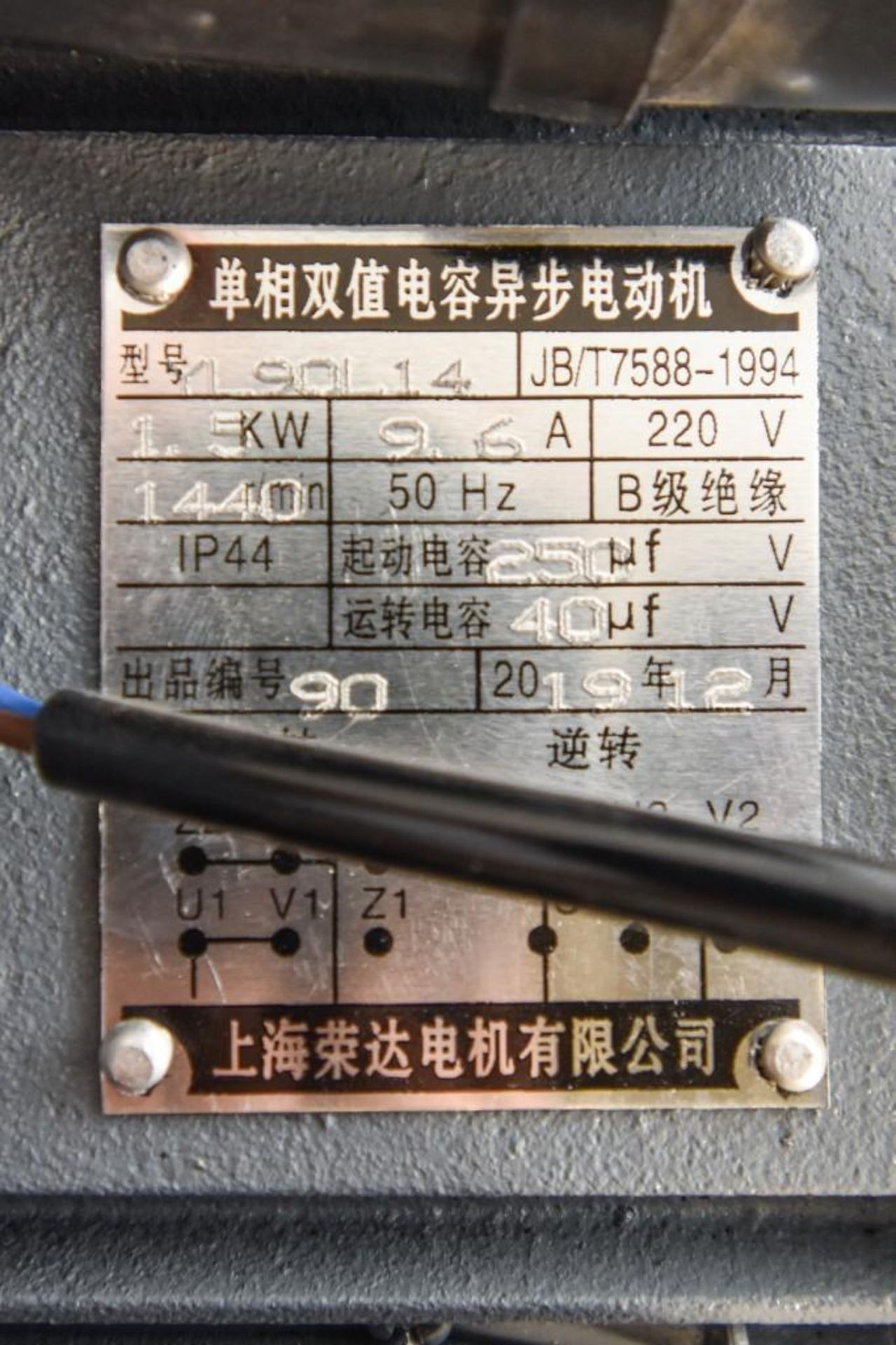

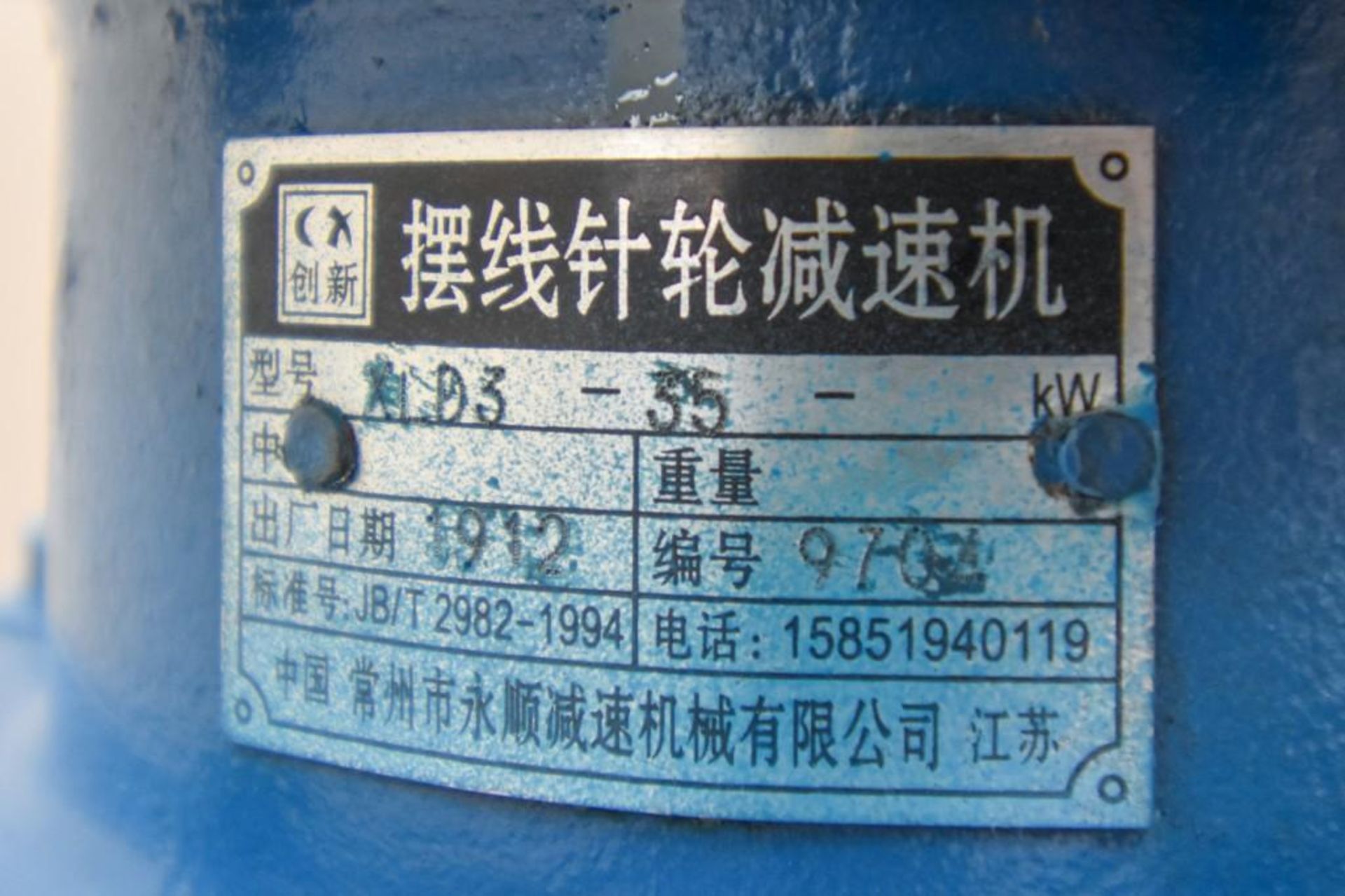

*Purchased new in 2020*

Cap Size: 3/4"

Dimensions: 52" x 39" x 69"H

Conveyor: 100" Long

Tank Dimensions: 36" x 52" x 68"H

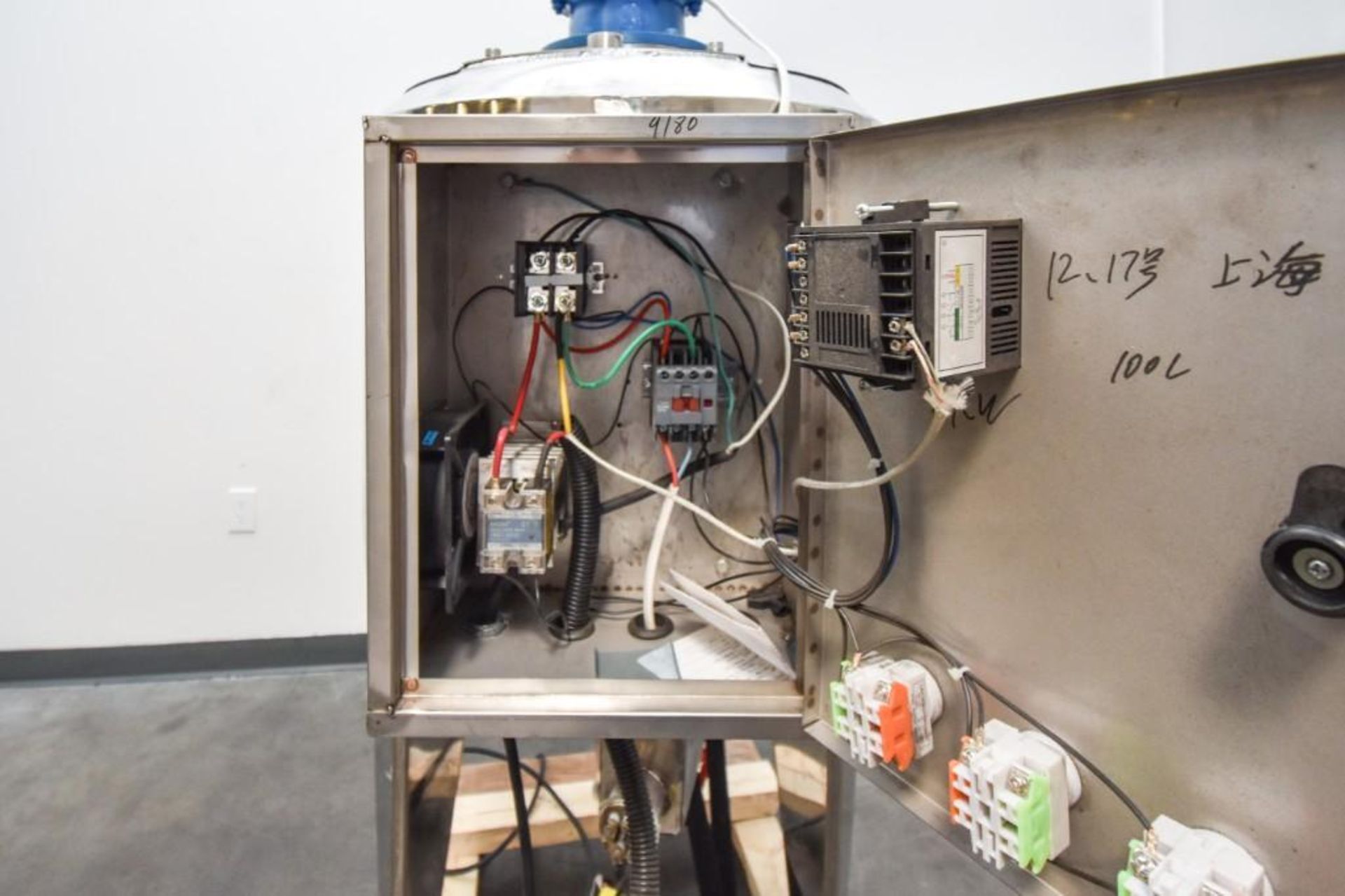

Tank Capacity: 100L

Vibratory Feeder Dimensions: 26" x 27" x 9"H

General Info:

A monoblock filling system is a packaging system that combines multiple pieces of packaging equipment on the same frame or chassis. The packaging equipment will almost always include a filling machine and capping or sealing equipment, though this is not a requirement. The monoblock filling system offers several advantages over automated, inline packaging systems.

In general, a monoblock filling system will consist of a starwheel that will move containers from one piece of packaging equipment to another by simply turning the starwheel in a consistent manner. One of the most obvious advantages of a monoblock filler is that the space required for the packaging equipment is reduced from that of traditional inline systems. Long and complex conveyor systems for transferring bottles or containers are replaced by a single starwheel. Individual, stand-alone packaging machines such as liquid fillers, capping machines, and container cleaning equipment are replaced by components serving the same function, but surrounding the starwheel. For facilities with limited space, the monoblock may be the only alternative for automating their packaging system.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Azusa Ca 91702

Skidding: $815

Load Out: $410

1 - Dual Head Liquid Filling/ Capping Machine with Vibratory Cap Feeder and Mixing Tank

*Purchased new in 2020*

Cap Size: 3/4"

Dimensions: 52" x 39" x 69"H

Conveyor: 100" Long

Tank Dimensions: 36" x 52" x 68"H

Tank Capacity: 100L

Vibratory Feeder Dimensions: 26" x 27" x 9"H

General Info:

A monoblock filling system is a packaging system that combines multiple pieces of packaging equipment on the same frame or chassis. The packaging equipment will almost always include a filling machine and capping or sealing equipment, though this is not a requirement. The monoblock filling system offers several advantages over automated, inline packaging systems.

In general, a monoblock filling system will consist of a starwheel that will move containers from one piece of packaging equipment to another by simply turning the starwheel in a consistent manner. One of the most obvious advantages of a monoblock filler is that the space required for the packaging equipment is reduced from that of traditional inline systems. Long and complex conveyor systems for transferring bottles or containers are replaced by a single starwheel. Individual, stand-alone packaging machines such as liquid fillers, capping machines, and container cleaning equipment are replaced by components serving the same function, but surrounding the starwheel. For facilities with limited space, the monoblock may be the only alternative for automating their packaging system.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Azusa Ca 91702

Skidding: $815

Load Out: $410

Liquid Manufacturing & Packaging Equipment

Ends from

General delivery information available from the auctioneer

Skidding and Load out charges:

There will be loading and skidding charges added to your purchase at market rates for your convenience.

Important Information

AUCTION DATE: lots start closing on Tuesday, May 31st, 2022 at 10:00 am PT

LOCATION: ***Mutliple Locations*** In Southern California.

INSPECTION: Please contact us to schedule. 818-495-3038

PICKUP/REMOVAL: TBD

RIGGING:

There is no self-rigging. All Rigging and Load out will be completed by a contracted and approved Rigger.

18% Buyers Premium applies on all online purchases.

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Friday, 8:00 AM EST – 8:00 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

Terms of Sale Agreement:

SELLER RESERVES THE RIGHT TO ACCEPT OR REJECT ANY AND ALL BIDS

- Only Credit Card, Wire Transfers or Cashier’s Checks payable to Chris Hillseth Enterprises will be accepted for payment. No equipment will be removed from the sale site until payment is received by Chris Hillseth Enterprises. NO EXCEPTIONS! NO PAYMENT TAKEN ON SITE.

- While descriptions are believed to be correct, the seller’s agent or the owners make no warranties or guarantees expressed or implied, as to the genuineness, authenticity of, or defect in any lot and will not be held responsible for advertising discrepancies or inaccuracies. Everything sold AS IS and WHERE IS except as expressly made in writing. No warranties are made as to the merchantability of any items or their fitness for any purpose. Inspect before you bid, absolutely no warranty or guarantee of any kind, either written or implied.

- For bidding approval, at its discretion, Chris Hillseth Enterprises Corp may contact Bidders via email or telephone before to provide a deposit. Require a deposit of up to $10,000.00 USD (refundable without purchase) for lack of sufficient Bidspotter history e.g. first time Bidspotter registrant or negative Bidspotter history. Bidder will be notified if it is determined a deposit must be made. If Chris Hillseth Enterprises does not receive a response from its attempts to contact Buyer or if the Buyer does not provide a deposit, Chris Hillseth Enterprises reserves the right to refuse or cancel Buyer’s bids and re-sell Goods.

- Some items may have minimums or reserves. Therefore, bidder acknowledges they have been informed that Auctioneer may bid at the auction for its own account or on behalf of a third party or the seller.

- Purchaser hereby agrees to defend, indemnify and hold harmless Seller its directors, officers, employees and other agents and representatives from and against any and all liabilities, judgments, claims, settlements, losses, damages, penalties, obligations and expenses, including attorney`s fees and expenses and other professional fees and expenses, incurred or suffered by such person arising from, by reason of, or in connection with any loss, damage or injury to person or property arising from, by reason of or in connection with the Goods sold hereunder. This indemnification shall survive delivery of the Goods to Purchaser and any subsequent sale or other transfer of the Goods to a third party.

- It is the buyers’ responsibility to secure all safety equipment to meet all applicable government safety standards in using or removing items purchased.

- Sales Tax will be added to the purchase of all taxable items. Dealers who purchase for resale must file their resale permit numbers. If sales tax is not collected at the time of sale and is deemed “needed to be paid” at a later date, buyer agrees to pay all required taxes.

- Purchaser does hereby indemnify and hold harmless auctioneer and seller from any and all damages, claims or liabilities from injuries to persons or property of any type whatsoever caused during the sale or by the removal of items purchased.

- Sellers agent and Seller shall have no liability to the purchaser due to non-delivery of any item for any reason other than to return to the Purchaser the monies deposited for non-delivered items.

- In the event the purchaser fails to pay the whole of the purchase within the time set forth by the auctioneers and/or fails to comply with any of the conditions or terms of sale, the seller may retain and/or recover the deposit specified as liquidated damages and, in addition thereto, items that are not paid for can be resold at public or private sale without further notice. Any deficiency resulting from such resale shall be paid to the auctioneers by the defaulting purchaser together with all charges, fees, and expenses incurred by such resale and enforcement of the obligation hereunder.

- The Bidder becomes solely responsible for all items purchased by him immediately following his winning bid at the auction. Therefore, he is advised to further guard and insure his items at his own discretion.

- No item can, on any account, be removed before buyer receives payment in full. Removal shall be at the expense, risk and liability of the purchaser. Auctioneers shall not be responsible for items not removed within the time allowed. If equipment is not removed within specified removal time, purchaser shall be liable for any moving and storage costs incurred and, if not so removed, the items shall be deemed abandoned.

- If any shortage exists on estimated counts, an adjustment will be made if claims are made at time of removal. No adjustment will be allowed after items are removed from the premises.

- If any dispute arises between two or more bidders, the sellers’ agent may or may not put the lot up again at once, and resell.

- The sellers’ agent, when acting as agent only, is not responsible for acts of its principals.

- A 18% Buyers premium will be applied to all sales in Addition to Applicable Local and State Sales Tax.

- By accepting a sale listing catalog and signing this form the buyer agrees to these terms and any announced terms at the sale.

- You will receive notifications from us regarding your purchases.

- Seller reserves the right to accept or reject any and all bids.

- All Bills must be completed on Day of Sale unless arrangements are made with Auction House prior to bidding.

- Full Payment at Termination of Sale.

- A 3% fee will be applied to all CC orders.

- Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates.

Inspection date (day only) is:

By Appointment Only. Call 818 495 3038 to Schedule.

Inspection locations:

Various Locations, call for specific item.

Inspection by appointment only.

Call or Email Logan Hillseth logan@chrishillsethenterprises.com or Patrick Hillseth at (818)495-3038 patrick@chrishillsethenterprises.com